Versatile application options

Versatile application options

Description/ features: this type of surface effect produces a concrete-look when the coating is applied. The special thing about this surface is that the effect can be applied to almost any substrate material imaginable and comes very close to the appearance of real concrete. The advantages of our Hesse Concrete effect are its quick and easy processing. In addition, this innovative effect is simple to achieve using standard Hesse products.

Fields of application : furniture and interior fittings.

How to achieve the concrete effect

How to achieve the concrete effect

- Sand the selected substrate material well (such as FPY or MDF priming foil, or melamine resin foil). We recommend substrate sanding at 150 to 240 grit. If you are working with bare MDF surfaces or edges, then we recommend prior sealing with Hesse PU Isolating filler DP 491-9343 or DP 4791-9343.

- Allow to dry for at least 3 h / 20 °C

- Then prime/prepare the substrate by spraying 1 x 180 to 200 g/m². (Caution: you will need large spray nozzles). To do this you need to mix the following components from isolating filler, cement and hardener: Mix Hesse PU Isolating filler DP 491-9343 or respectively DP 4791-9343, mixing ratio (gravimetric) 10 : 4 with commercially available cement. You then need to blend this mixture uniformly. Finally add the hardener to this filler/cement mixture, mixing ratio (by volume) 4 : 1 with Hardener DR 405 or respectively Hardener DR 4058. As required, and depending on the part, you can add 10 - 15 % Thinner DV 490 or respectively DV 4900 to the filler/cement/hardener mixture.

- After a brief period of initial drying you can now create the actual concrete effect using a palette knife. You achieve the basic structure of the concrete-look with uniform, straight or individual swirling movements of the pallet knife. Although it is also possible just to spray the filler/cement mixture in order to retain a uniform concrete effect.

- After drying for a minimum of 16 h / 20 °C you can proceed with a surface or effect sanding using 220 to 240 grit. You can also achieve whatever look you like by removing different layers when sanding (by hand, random orbital sander or sanding machine). • You now uniformly spray a generous coat of Hesse Colour stain BC 85-22736 to obtain the typical concrete shade. This is followed by wiping for effect, which achieves that certain patina effect (such as by using a gauze bale or a sponge). • After around 2 h / 20 °C, you need to add a top coat of Hesse Multicoat lacquer UNA-PUR DE 55x(gloss level) or respectively Hesse UNA-PUR DE 4259x(gloss level) in the desired gloss level. In this case the usual mixing ratio (by volume) 10 : 1 with Hardener DR 4070 can be followed.

What distinguishes the concrete effect?

What distinguishes the concrete effect?

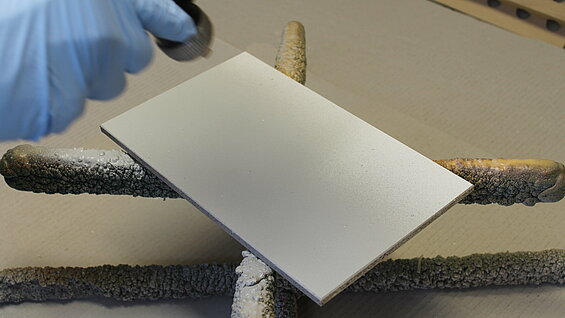

Here’s a detailed view of the finished surface.

Technical information Concrete effect

Products required

Please observe the latest technical information and the material safety data sheets for the stated individual products. Particular instructions: PU lacquers should not be processed and dried at material and room temperatures below 18 °C. PU lacquered surfaces should be freshly sanded before finishing to avoid adhesion problems.

Warning: Please observe the precise addition of hardeners and thinners in the information below.

NoteThis information is purely advisory and is based on the best knowledge available after careful research in line with current state of the art technology. It is not legally binding. We also refer you to our Terms and Conditions. The material safety data sheet according to regulation (EC) No. 1907/2006 is available on request.

Contact partner