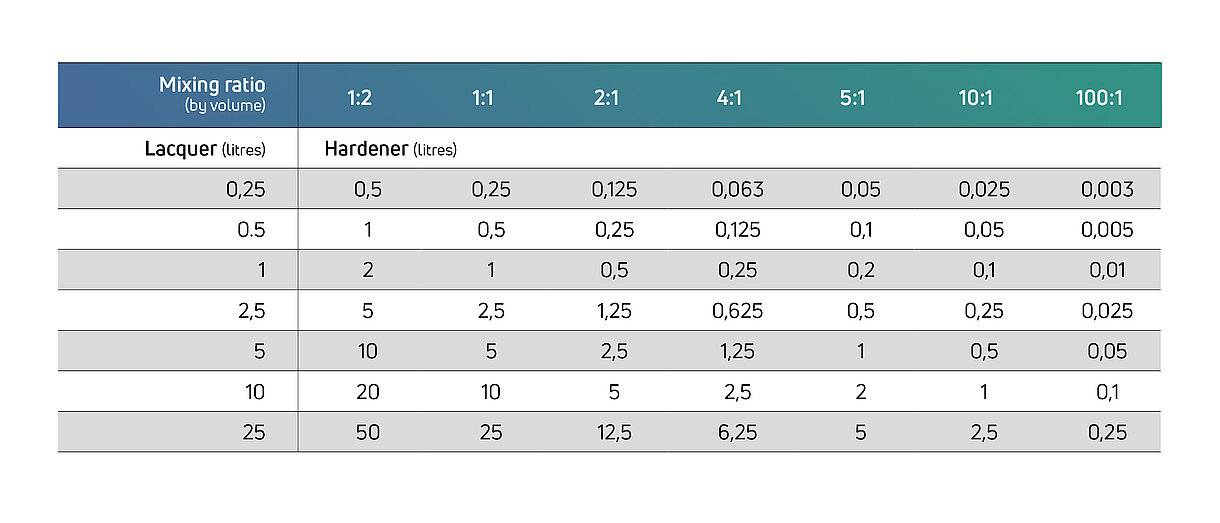

Table providing an overview

The two components, the lacquer and the appropriate hardener, need to be mixed together before the lacquer can be used. This should be done in accordance with the mixing ratio specified on the label or in the lacquer’s technical information. But what does a mixing ratio (by volume) 10 : 1 actually mean? A mixing ratio 10 : 1 means that you need 10 parts of lacquer and 1 part hardener. As the mixing ratio here is given by volume, the component parts have to be measured according to volume too (i.e. in litres). A suitable measuring container will obviously be useful. If you want to harden 5 litres of our 2C water-based lacquer, then you’ll need to add 0.5 litres of the appropriate hardener.

But what if your Hesse product is very dense, and is sold in kilograms rather than litres? You can still use a suitable measuring container to measure out the correct amounts of lacquer and the appropriate hardener. Mixing ratios are alternatively stated gravimetrically, or by weight. A lacquer quantity of 7 kg of PU Filler and a mixing ratio (gravimetric) 100 : 7 accordingly means that 0.49 kg of hardener needs to be weighed and mixed in. 100 parts of lacquer and 7 parts of hardener.