PU Basecoat DG 4768-0004

Hesse PU Basecoat DG 4768-0004 is a two-component PU polyester resin basecoat. The lacquer sands well, is extremely elastic and has good coverage. It also fulfills the requirements of the IMO EC Type Examination test certificate (flame retardant coating agent for seagoing vessels).

Enquire articlePage content

- IMO-approved

- Thixotropic

- very well filling

- Good sanding properties

- also for kitchen and bathroom furniture

Processing

- mineral resources 1%

- fossil resources 99%

Areas of application

Hesse PU basecoat is particularly suitable for achieving closed-pore lacquer structures beneath Hesse PU multicoat lacquers and top coats. This basecoat has great filling power and is used primarily in the high quality fit-out of ships, the interior design sector and shopfitting.

Technical information

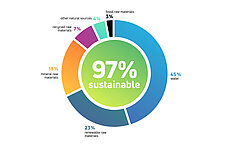

Sustainability data sheet

Certificates

Technical Specifications

| Proportion of renewable raw materials % | 0 % |

|---|---|

| Appearance | colourless |

| VOC EU % | 60,5 % |

| Number of layers (max) | 12 |

| Quantity per layers (min) | 100 g/m² |

| Quantity per layers (max) | 200 g/m² |

| Total quantity applied | 2400 g/m² |

| Mixing ratio (volumetric) | 2 : 1 | Hardener: DR 4035-0001 |

| Mixing ratio (gravimetric) | 100 : 51 | Hardener: DR 4035-0001 |

Processing Instructions

| Potlife | 2 h / 20 °C |

|---|---|

| Drying | 6 h / 20 °C |

| Due to hardening | 7 d / 20 °C |

| Stackable according to | 16 h / 20 °C |

| Surface sanding (grain size) | 150 - 180 |

| Intermediate sanding (grain size) | 320 - 400 |

| Yield per pass | 5 - 10 m²/l |

| Special notes | We recommend pre-priming with Hesse PU Isolating primer DG 4720-0001 to improve the stability and bonding to critical woods such as tropical woods and cherry. This product must only be combined with other approved and technically suitable products when used as a flame retardant coating material for seagoing vessels according to the latest version of SOLAS 74 Reg. II-2/3, II-2/5, II-2/6 and X/3, as amended, IMO Resolution MSC.36(63)-(1994 HSC-Code) 7, IMO Resolution MSC.97(73)-(2000 HSC-Code) 7, IMO MSC/Circ. 1120. The maximum application amount in wet film when using this product as a flame retardant coating material for seagoing vessels is 150 g/m². Can be recoated after sufficient drying time and following the specified sanding, e.g. with DU 4812x(gloss level), DU 4401x(gloss level)-0001, DE 4259x(gloss level). “A risk assessment was undertaken according to Directive 2014/90/EU, Annex II, Section 3. This coating does not pose a physical risk to health nor a risk to the environment when cured and dried.” |

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.