PU Colour Coat DB 45205-(colour)

DB 45205-(colour tone) is a light fast PU colour lacquer combined with a thixotropic lacquer formulation for easy application on vertical surfaces or components. Its excellent adhesion properties on almost all substrates, its uncomplicated application and a pot life of 3 days make this colour lacquer ideal for universal use. DB 45205-(colour tone) can be coated with all customary intermediate and finishing lacquers for optimal metal marking resistance.

Enquire articlePage content

- uncomplicated application to vertical surfaces

- universally applicable

- outstanding adhesion properties

- 3-day pot life

Processing

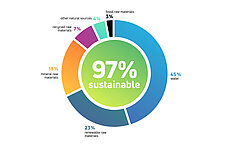

- renewable resources 1%

- mineral resources 20%

- fossil resources 79%

Areas of application

Not suitable for applications within the scope of ChemVOCFarbV or of EU Directive 2004/42/EC (Decopaint).

Technical information

Sustainability data sheet

Certificates

Technical Specifications

| Appearance | opaque |

|---|---|

| Number of layers (max) | 2 |

| Quantity per layers (min) | 80 g/m² |

| Quantity per layers (max) | 150 g/m² |

| Total quantity applied | 300 g/m² |

| Mixing ratio (volumetric) | 10 : 1 | Hardener: DR 4070 |

| Mixing ratio (gravimetric) | 100 : 9 | Hardener: DR 4070 |

Processing Instructions

| Potlife | 3 d / 20 °C |

|---|---|

| Drying | 3 h / 20 °C |

| Due to hardening | 7 d / 20 °C |

| Stackable according to | 16 h / 20 °C |

| Surface sanding (grain size) | 150 - 320 |

| Intermediate sanding (grain size) | 320 - 400 |

| Yield per pass | 7 m²/l |

| Processing information | The maximum total application amount when being used as a flame-retardant coating agent for seagoing vessels is 130 g/m². When directly coating cleaned or sanded foils, please apply a test coat to check the bonding. For particular strains on the surface and on critical carriers, harden with DR 4070 to the ratio of 5 : 1. A hardening additive ratio of 10 : 1 with DR 4071 is necessary for direct coatings onto MDF. A hardening additive ratio of 10 : 1 can accelerate complete drying (pay attention to shorter potlife here). The hardening additive ratio of 5 : 1 with DR 4076-0001 following prior mixture of 5 % Glass lacquer additive EL 460-0025 to lacquer products also makes it possible to apply the lacquer directly onto glass following prior cleaning in accordance with regulations. |

| Special notes | When used as low-flammable coating for seagoing vessels according to SOLAS 74 Reg. II-2/3, II-2/5, II-2/6 and X/3, as amended, IMO Resolution MSC.36(63)-(1994 HSC-Code) 7, IMO Resolution MSC.97(73)-(2000 HSC-Code) 7, IMO MSC/Circ. 1120, this product can only be combined with other approved and technically suitable products. Prepriming is possible depending on surface requirements and substrate, e.g. with DP 4755-9343 and DP 4791-9343. If absolute ring and colour rub resistance or a different gloss level is desired, we recommend Top coat with e.g. Hesse MEGA-PU DE 4503x(gloss level) or Hesse UNA-PU DE 4259x(gloss level)."A risk assessment has taken place in accordance with Directive 2014/90/EU, Annex II, Section 3. The cured and dried coating poses no physical or health risk, nor any risk to the environment." |

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.