EAZYPORE-OIL OTEP (color tone)

Hesse EAZYPORE-OIL is a fast-drying mixture of different natural oils that has a inoffensive smell.

modified Alkyd resins; tinted using particularly light fast special pigments. It is primarily used as a fast-drying, solvent-based 2K oil for contrasting emphasis of the pores in coarse pored woods. Exclusive selection of modern raw materials results in it not being subject to labelling under the latest version of the CLP Regulation. It meets the requirements of EN 71-3 (11-2014) and is therefore suitable for use on children's toys.

Enquire articlePage content

- light fast special pigments

- good resistance against household chemicals

- fast-drying

- no requirement for labelling under the GHS/CLP Regulation

Processing

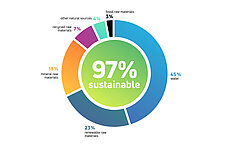

- renewable resources 10%

- mineral resources 8%

- fossil resources 82%

Areas of application

Creating a coloured effect on furniture, parquet surfaces and stair treads with normal to high use in interiors.

The colour tone, effect and mechanical resistance depend on the number of coats of oil

that are applied.

EAZYPORE-OIL can even be applied directly onto bare wood or wood stained with the likes of WPB Stains and then fixed using most standard oils to achieve special colour effects.

Technical information

Sustainability data sheet

Certificates

Technical Specifications

| Appearance | not relevant |

|---|---|

| Number of layers (max) | 1 |

| Quantity per layers (min) | 10 g/m² |

| Quantity per layers (max) | 30 g/m² |

| Total quantity applied | 30 g/m² |

| Mixing ratio (volumetric) | 100 : 4 | Hardener: OR 5180 |

| Mixing ratio (gravimetric) | 100 : 5 | Hardener: OR 5180 |

Processing Instructions

| Due to hardening | 7 d / 20 °C |

|---|---|

| Surface sanding (grain size) | 120 - 320 |

| Intermediate sanding (grain size) | |

| Yield per pass | 35 - 105 m²/l |

| Processing information | EAZYPORE-OIL should be hardened in a 25 : 1 ratio with OIL-HARDENER HIGH-SOLID OR 5180. Please stir the hardener in well. and use the hardened mixture within 8 h.Manual application:use a putty knife, brush or roller to apply thinly and, especially in the pore area, work it in uniformly using the likes of a fine sanding fleece or cotton cloth. Allow a brief exposure time and then use a rubber scraper, putty knife, "squeegee" or soft cotton cloth to remove the excess, especially in the hard part of the figure, until the entire surface appears uniformly dry and the pore area is appropriately emphasised. Drying time: at least 16 h / 20 °C room temperature and with adequate air exchange. The EAZYPORE-OIL must then be fixed! Larger surface areas should be coated by two people.In the furniture sector:after sufficient drying, EAZYPORE-OIL OTEP 750 must be fixed using a natural oil like NATURAL-OIL OE 52832 or PROTECT-OIL OE 52842. EAZYPORE-OIL can as necessary also be fixed using matching HYDRO lacquers. . Such as our PERFECT-TOP HDE 5400x(gloss level).For use on parquet flooring:Use a suitable putty knife to apply the material. Allow a brief exposure time and then use a single-disc sander with non-abrasive white pad to work it in uniformly until the surface appears dry. Use a rubber scraper, putty knife or squeegee to remove the excess in such a way that the EAZYPORE-OIL still accentuates the pores, yet the hard part of the figure is mostly clear. If necessary, use a single-disc sanding machine with a non-abrasive (white) pad or cotton cover to rework the hard part of the figure.After sufficient drying, the EAZYPORE-OIL must be fixed using matching HYDRO-SEALS. |

| Special notes | General combination options with EAZYPORE-OIL:Raw wood1 x WPB stain1 x Hesse EAZYPORE-OIL OTEP (color tone)2 x oil or1 - 2 x finish with suitable hydro lacquersor raw wood1 x Hesse EAZYPORE-OIL OTEP (color tone)Oil 2 x orFinish 1 - 2 x with suitable hydro lacquersBrightening possible with: OE 52832 or OE 52839 The material is not suitable for wood susceptible to blue stain in damp rooms. The material properties have been tested on commercially available woods such as Oak, Beech etc. For use on other types of wood, please check suitability prior to use. Processing time of the mixture 1 h / 20 °C room temperature. The chemical and mechanical resistance depends on the number of layers of oil applied. The material dries by oxidation, please follow the general instructions for processing. The parquet must not be covered with foils or carpets before reaching final hardness. Due to the high reactivity, skin formation may occur. Please remove before stirring. The material should then be sieved as a precaution. Stir carefully before use. Please observe the latest material safety data sheet!As additional protection against pigment abrasion on coloured oil surfaces subject to particularly heavy use, the EAZYPORE-OIL surface should then be given a final treatment with a clear oil. NATURAL-OIL OE 52832 can generally be used for this purpose. For light colour tones, PROTECT-OIL OE 52842 is recommended due to its light inherent colour and excellent light resistance for an oil.When using EAZYPORE-OIL between or under NATURA-OIL OE 52832 or NATURAL-SOLID-OIL GE 11254 products, experience has shown that hardening can be dispensed with in most cases.To be on the safe side, we recommend producing a test surface on the original substrate with the planned original structure. |

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.