PERFECT-COLOR HDB 5434x(gloss level)-(colour tone)

The HYDRO color lacquer PERFECT-COLOR HDB 5434x(gloss level)-(colour tone) gives you an excellent color lacquer surface that is particularly resistant to mechanical and chemical stress. PERFECT-COLOR is easy to process thanks to its excellent flow properties. Its fast complete drying and the option of forced drying make it possible to stack or process even heavy workpieces the very next day. PERFECT-COLOR is a light fastness top coat for priming and top coating. PERFECT-COLOR can also be applied directly to sanded raw MDF edges and surfaces.

Enquire articlePage content

- fast drying

- outstanding levelling

- heavy-duty surface

- forced drying is possible so processing can quickly continue

- can be directly applied onto MDF and MDF edges

Processing

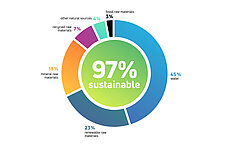

- water 52%

- mineral resources 22%

- fossil resources 26%

Areas of application

PERFECT-COLOR s particularly suitable for industrial coating in the interior fittings and shop fitting sectors and for contract installations including doors, bathrooms and kitchens. This colour lacquer is also suitable for reverse glass coating of decorative glass surfaces.

Technical information

Sustainability data sheet

Certificates

Technical Specifications

| Appearance | opaque |

|---|---|

| Decopaint base | wb |

| Decopaint category | J |

| Number of layers (max) | 2 |

| Quantity per layers (min) | 120 g/m² |

| Quantity per layers (max) | 140 g/m² |

| Total quantity applied | 240 g/m² |

| Mixing ratio (volumetric) | 10 : 1 | Hardener: HDR 5091 |

| Mixing ratio (gravimetric) | 100 : 10 | Hardener: HDR 5091 |

Processing Instructions

| Drying | 9 h / 20 °C |

|---|---|

| Due to hardening | 7 d / 20 °C |

| Stackable according to | 16 h / 20 °C |

| Surface sanding (grain size) | 120 - 400 |

| Intermediate sanding (grain size) | 280 - 600 |

| Yield per pass | 9 m²/l |

| Processing information | Add hardener slowly whilst stirring and adjust the spray viscosity by adding water or HYDRO Optimizer HZ 70, if required. Maximum additive volume 5 %. The hardener must always be added before thinning! The flow time should not be less than 40 s / DIN 4 mm after hardening and thinning. Never store product mixed with hardener in closed containers. Clean tools with water. For removal of dried lacquer residues use Hesse HYDRO Cleaning agent HV 6917. In case of combined coatings (HYDRO- and solvent based lacquers) rinse application tools with Hesse HYDRO Reversing agent HV 6904. |

| Special notes | Pre-priming is possible depending on the required finish and carrier material, for instance using: HP 6645-9343, HDP 5650-9343, DP 4755-9343. Pre-prime exotic woods such as Macassar or extremely resinous knotty pine with PU sealing primer DG 4720-0001. When used on staircases (treads) we recommend finishing the colour lacquer surface with Hesse PERFECT-TOP HDE 5400x(gloss level) or other Hesse HYDRO staircase lacquers.This product must only be combined with other approved and technically suitable products when used as a flame retardant coating material for seagoing vessels according to the latest version of SOLAS 74 Reg. II-2/3, II-2/5, II-2/6 and X/3, as amended, IMO Resolution MSC.36(63)-(1994 HSC-Code) 7, IMO Resolution MSC.97(73)-(2000 HSC-Code) 7, IMO MSC/Circ. 1120. The maximum application amount in wet film when using this product as a flame retardant coating material for seagoing vessels is 120 g/m².Our PERFECT-COLOR can also be used in the original mixing ratio for reverse glass coating of decorative glass surfaces. The glass surface must be clean and grease-free prior to application.For surfaces subject to heavy use or direct contact with water, we recommend our special Glass lacquer HDB 57485-(colour tone).“A risk assessment was undertaken according to Directive 2014/90/EU, Annex II, Section 3. This coating does not pose a physical risk to health nor a risk to the environment when cured and dried.” |

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.