RAPID-ISO-FILL DP 4764-9343

A pigmented two-component PU alkyd primer, fast drying and sands to a powder. Hesse RAPID- ISO-FILL DP DP 4764-9343 is a filling primer for coloured and closed-pore buildup of coloured lacquers.

Enquire articlePage content

- Isolation primer

- fast-drying

- Can be sanded to a powder

Processing

Areas of application

For all interior fittings, including in kitchens, shop counters and bathrooms. Hesse RAPID-ISO-FILL can be applied to various types of wood, priming foil and as direct coating on MDF, including edges.

Technical information

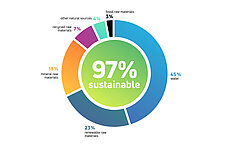

Sustainability data sheet

Technical Specifications

| Appearance | opaque |

|---|---|

| Number of layers (max) | 4 |

| Quantity per layers (min) | 140 g/m² |

| Quantity per layers (max) | 300 g/m² |

| Total quantity applied | 800 g/m² |

| Mixing ratio (volumetric) | 2 : 1 | Hardener: DR 4033 |

| Mixing ratio (gravimetric) | 100 : 32 | Hardener: DR 4033 |

Processing Instructions

| Potlife | 1,2 h / 20 °C |

|---|---|

| Drying | 3 h / 20 °C |

| Due to hardening | 7 d / 20 °C |

| Stackable according to | 16 h / 20 °C |

| Surface sanding (grain size) | 150 - 320 |

| Intermediate sanding (grain size) | 320 - 400 |

| Yield per pass | 5 m²/l |

| Special notes | As necessary, Hesse RAPID-ISO-FILL DP 4764-9343 can be hardened with Hesse PU Hardener DR 4036 to accelerate thorough drying. The open time when hardener is added is 30 minutes / 20 °C! In this paint/hardener combination, we recommend the use of two-component spraying equipment. For MDF substrates: With MDF coatings, you can avoid painting faults and edge breaks if you observe the following: Selection of an MDF quality suitable for the field of application, see manufacturer data on EU standard EN 622-5 pt.4 Test methods EN 317 (requirements on thickness swelling). Ideal panel moisture 5 - 7 %. If possible coat the MDF all around, the backs should at least receive a clear coating. Avoid sharp edges and milling grooves, round-off wherever possible. Coat edges and milling grooves 2 x with primer, do not sand through, if need be, prime again. Thick boards that have been built by gluing together several thinner boards are, due to the variance in tension, susceptible to edge ridging. It is better to select a single MDF board of the appropriate thickness. Panels that have been glued together should always be sanded flat at the edges and colourlessly pre-insulated. Any water introduced by the gluing process must be allowed to evaporate prior to coating. Store filler-coated surfaces in an air conditioned location and apply the final coat in a timely manner. |

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.