Acrylic Brilliant Lacquer DU 46269-0005

Crystal clear, high gloss, and full of depth characterize the acrylic brilliant lacquer as a top coat for colored lacquer surfaces. Thanks to its excellent light fastness, this gloss is retained over the long term, even under intensive use. With standard polishing and buffing machines, the lacquer can be brought to a mirror-like high gloss without much effort. Natural wood and peroxide-bleached wood types also reveal their full effect under this clear lacquer – provided they have been prepared beforehand with transparent PUR primers. The result is a surface that not only impresses technically, but also inspires emotionally: clear, brilliant, and elegant.

Enquire articlePage content

- High-gloss, lightfast, and extremely brilliant

- Suitable for bleached wood types

- Can be polished and buffed

- Complies with the See-BG / IMO test certificate

Processing

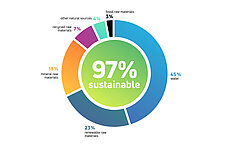

- mineral resources 1%

- fossil resources 99%

Areas of application

Versatile use in all aspects of shop and interior design. Also perfect for high-quality kitchen and bathroom designs.

Technical information

Sustainability data sheet

Certificates

Technical Specifications

| Proportion of renewable raw materials % | 0,00 % |

|---|---|

| Appearance | colourless |

| VOC EU % | 53,74 % |

| Number of layers (max) | 2 |

| Quantity per layers (min) | 100 g/m² |

| Quantity per layers (max) | 150 g/m² |

| Total quantity applied | 300 g/m² |

| Mixing ratio (volumetric) | 2 : 1 | Hardener: DR 4078 |

| Mixing ratio (gravimetric) | 100 : 50 | Hardener: DR 4078 |

Processing Instructions

| Potlife | 5 h / 20 °C |

|---|---|

| Drying | 2 d / 20 °C |

| Due to hardening | 7 d / 20 °C |

| Stackable according to | 3 d / 20 °C |

| Surface sanding (grain size) | 400 - 800 |

| Intermediate sanding (grain size) | 600 - 800 |

| Yield per pass | m²/l |

| Processing information | DU 46269-0005 can be polished after 48 hours at 20 °C and a humidity of 40–45%. These specifications may vary in significantly different climatic conditions and must be checked individually if necessary. The processing viscosity must be adjusted by the user. We recommend adding 20–30% DV 4935 thinner to the paint/hardener mixture.Pre-priming is possible depending on the desired surface finish and substrate, e.g., with the primers MEGA-PUR Grund DG 4717-0005, PUR-Grund DG 4760 primers or the FANTASTIC-COLOR DB 4888x(gloss level)-(color tone) and UNA-COLOR DB 4524x(gloss level)-(color tone) color lacquer series. DU 46269-0005 should be used on bleached wood types in combination with MEGA-PUR Grund DG 4717-0005.If a high-gloss surface with particularly high scratch resistance is required, we recommend using the transparent high-gloss lacquer ADAMANT DU 48999. Please refer to the separate technical information for this product. |

| Special notes | This product must only be combined with other approved and technically suitable products when used as a flame retardant coating material for seagoing vessels according to the latest version of SOLAS 74 Reg. II-2/3, II-2/5, II-2/6 and X/3, as amended, IMO Resolution MSC.36(63)-(1994 HSC-Code) 7, IMO Resolution MSC.97(73)-(2000 HSC-Code) 7, IMO MSC/Circ. 1120. The maximum application amount in wet film when using this product as a flame retardant coating material for seagoing vessels is 120 g/m².“A risk assessment was undertaken according to Directive 2014/90/EU, Annex II, Section 3. This coating does not pose a physical risk to health nor a risk to the environment when cured and dried.” |

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.