PU Mirror lacquer DB 46334-M0966

Hesse PU Mirror effect lacquer DB 46334-M0966 is a light-fast, two-component PU Effect lacquer for glass coating. This fast-drying lacquer with its very good adhesion properties is particularly suitable for exceptional and creative surfaces on white glass. With little effort and by using the Hesse Effect agent DZ 4992-05856 combined with the mirror lacquer an antique effect can be achieved impressively.

Enquire articlePage content

- Light-fast

- outstanding adhesion

- Fast-drying

- individual antique effect possible

Processing

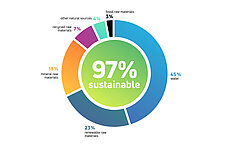

- mineral resources 1%

- fossil resources 99%

Areas of application

DB 46334-M0966 can be used for the complete interior decoration for the living area on white glass, but as well on structured glass with a suitable protective top coating e.g. DB 42105-(colour tone).

Technical information

General technical information

Sustainability data sheet

Technical Specifications

| Proportion of renewable raw materials % | 0,00 % |

|---|---|

| Appearance | opaque |

| VOC EU % | 98,71 % |

| Number of layers (max) | 1 |

| Quantity per layers (min) | 60 g/m² |

| Quantity per layers (max) | 80 g/m² |

| Total quantity applied | 80 g/m² |

| Mixing ratio (volumetric) | 25 : 1 | Hardener: DR 4076-0002 |

| Mixing ratio (gravimetric) | 100 : 4 | Hardener: DR 4076-0002 |

Processing Instructions

| Potlife | 8 h / 20 °C |

|---|---|

| Drying | 1 h / 20 °C |

| Due to hardening | 7 d / 20 °C |

| Stackable according to | 16 h / 20 °C |

| Surface sanding (grain size) | |

| Intermediate sanding (grain size) | 320 - 400 |

| Yield per pass | 11 - 15 m²/l |

| Processing information | The substrate must be cleaned and degreased thoroughly with Hesse Glass cleaner. The proper preparation of the substrate is decisive for the adhesion of the lacquer. |

| Special notes | In case of back-varnishing of glass the inherent colour of the glass affects the subsequent colour tone and effect. If Hesse PU Mirror effect lacquer DB 46334-M0966 shall be used we recommend the application on white glass. Metallic lacquers must always be applied evenly. The application amount, application method and drying conditions affect the colour tone and the effect. If required, please make a test coating under practical conditions. |

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.