2C HYDRO-PU Brilliant lacquer HDE 54799

Two component HYDRO-PU acrylate lacquer with good body, water soluble, clear, high gloss and with outstanding chemical and mechanical resistance. It can be polished and buffed, PVC-resistant, cream and sweat resistant and light fast. Free from N-methylpyrrolidone and phthalate plasticisers, therefore also suitable for coating children's toys.

Artikel anfragen- Good body

- Good transparency

- Light-fast

- outstanding chemical and mechanical resistance

- good polishing and buffing properties

Processing

Areas of application

For high quality residential furniture with high-demand surfaces and all interior fittings, including those in kitchens and bathrooms. Can also be used on bleached surfaces (that are adequately dry).

Page content

Technical information

Sustainability data sheet

Certificates

Technical Specifications

| Proportion of renewable raw materials % | 5,931 % |

|---|---|

| Appearance | colourless |

| Decopaint base | wb |

| Decopaint category | J |

| VOC EU % | 4,1 % |

| Number of layers (max) | 3 |

| Quantity per layers (min) | 100 g/m² |

| Quantity per layers (max) | 150 g/m² |

| Total quantity applied | 450 g/m² |

| Mixing ratio (volumetric) | 5 : 1 |

| Mixing ratio (gravimetric) | 100 : 21 |

Processing Instructions

| Potlife | 2 h / 20 °C |

|---|---|

| Drying | 16 h / 20 °C |

| Due to hardening | 7 d / 20 °C |

| Stackable according to | 3 d / 20 °C |

| Surface sanding (grain size) | 320 - 600 |

| Intermediate sanding (grain size) | 400 - 600 |

| Yield per pass | 7 - 10 m²/l |

| Processing information | Sanding of the basecoat with 400 - 600 grit / dust removal. Work the hardener in well, then use water (around 20 %) to adjust the spray viscosity to 20 - 25” (DIN 4 mm). The hardener must always be added before thinning! Never store product mixed with hardener in closed containers. Only ever apply 1 coat of at most 120 g/m² in one operation. Do not apply several thin coats with brief intermediate drying, as may be common with other high gloss systems. Drying of the first coat until application of the subsequent:: 5 - 6 h at 20 °C room temperature and with adequate air circulation. Recoatability: with itself following proper sanding. Clean tools with water. For removal of dried lacquer residues use Hesse HYDRO Cleaning agent HV 6917. In case of combined coatings (HYDRO- and solvent based lacquers) rinse application tools with Hesse HYDRO Reversing agent HV 6904. |

| Special notes | Also suitable for top-coating on coloured HYDRO surfaces. Pre-priming is possible, depending on the desired surface and the substrate material, e.g. with HDG 5407 and by request also on various PU systems. HYDRO-PU Multicoat lacquers and top coats are optimised for use on 2-coat hydro systems. Clean tools with water. For removal of dried lacquer residues use Hesse HYDRO Cleaning agent HV 6917. In case of combined coatings (HYDRO- and solvent based lacquers) rinse application tools with Hesse HYDRO Reversing agent HV 6904.“A risk assessment was undertaken according to Directive 2014/90/EU, Annex II, Section 3. This coating does not pose a physical risk to health nor a risk to the environment when cured and dried.” |

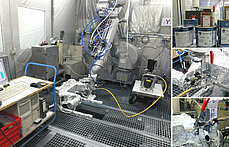

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.