LED technology has been known for many years as an energy-saving technology; including for hardening UV lacquers. But it hasn’t yet become established in the furniture and timber industry: there are only a few manufacturers in Europe who fully rely on this technology.

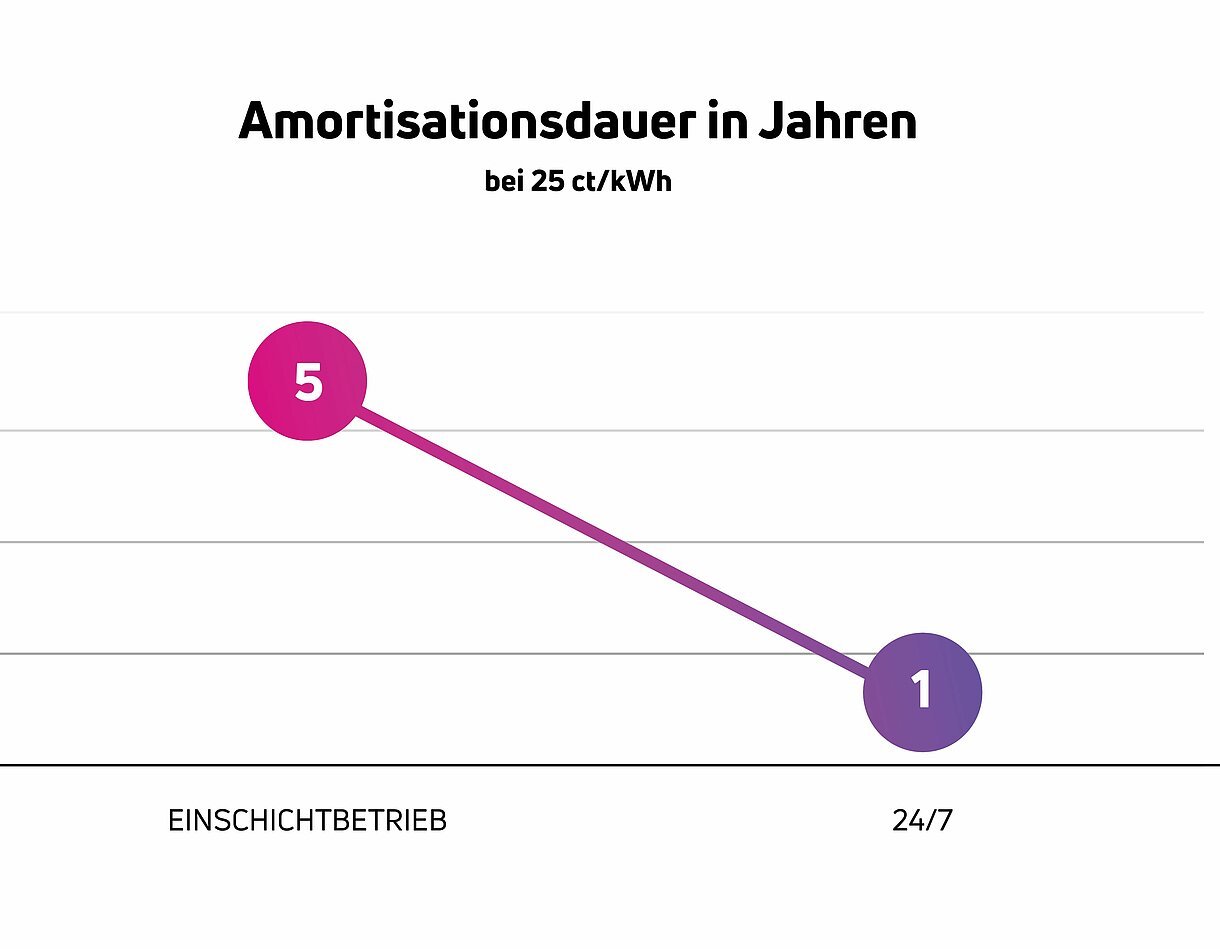

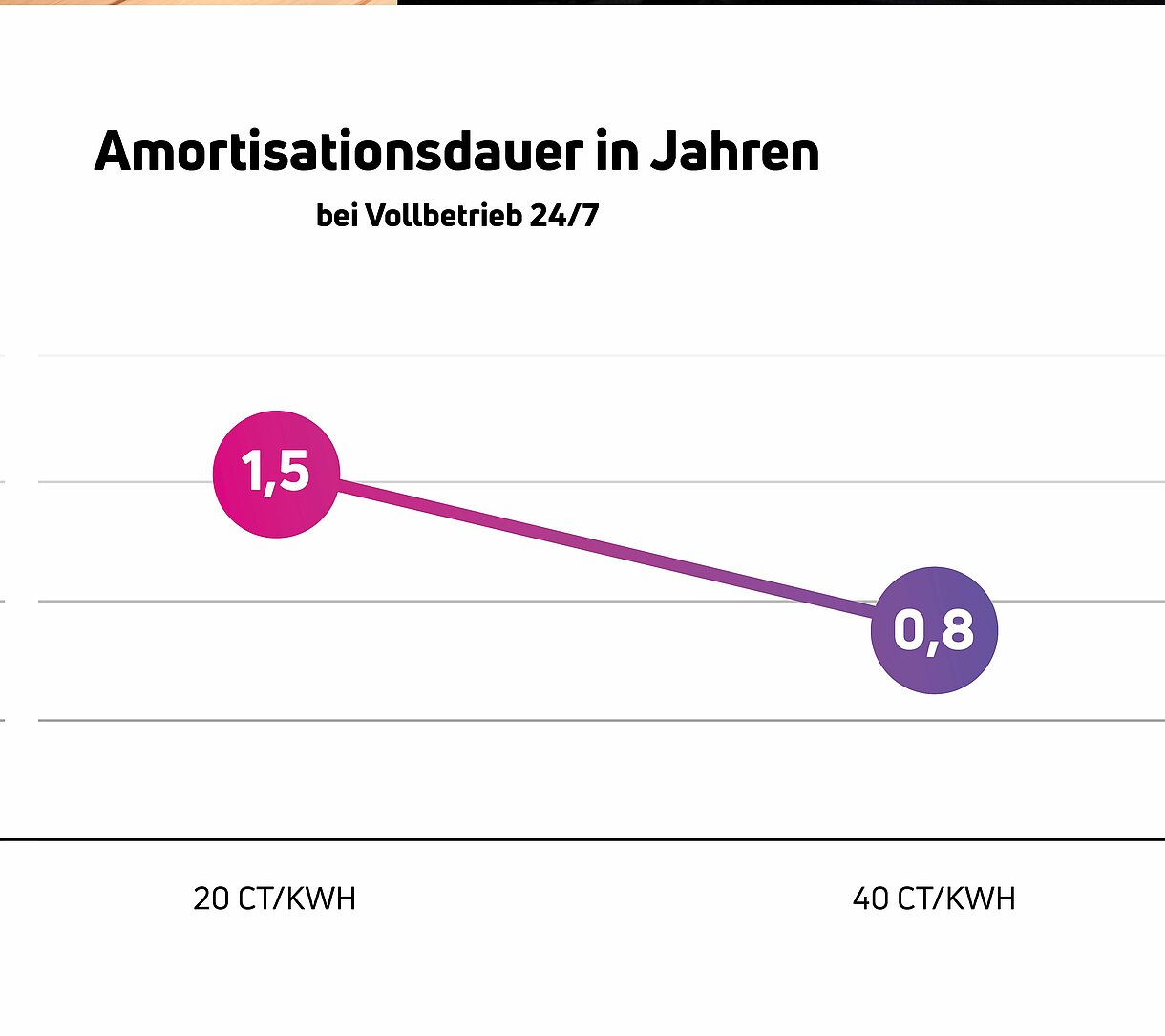

The current explosion in energy prices makes it even more worthwhile to add this topic back onto the agenda.

What are the benefits of LED lamps?

Many hardening processes can already be performed using LED lamps. This applies both to pigmented and clear lacquers. But there is one restriction: conventional lamps are still needed in the final coating area. Depending on the system configuration, a number of UV lamps could be replaced by modern LED lamps, such as for hardening basecoats or for gelling. It’s also often possible to replace combinations of several lamps with just one LED lamp. Other properties worth mentioning include:

- Feed rates of up to 50m/min can be realised.

- No use of heavy metals in the lamps

- Future-proof given the impending ban relating to mercury in lamps

- Short switch-on and switch-off times, no cooling down or slow start-up of the lamps

- This allows lamps to be switched off during short or clocked process pauses

- Less distance to the workpiece (10 - 70mm) than with traditional lamps

- Very low heat generation, resulting in longer service life of sanding belts

- 4 times longer lamp life