Efficient coating with UV hardening

Using LED beam technology for the perfect surface

LED isn’t just an issue when its comes to lighting. Energy-saving LED technologies are also used for surface finishing in the wood processing industry.

UV hardening systems that make use of LED technology have been deployed in the industry for some years now. This requires special UV lacquers. Hesse Lignal even sells lacquers appropriate for this technology which enable complete energy-saving hardening.

The advantages at a glance

Energy efficient coating with LED lacquer technology

-

Low energy consumption in comparison to conventional UV lamps

-

Very brief activation times

-

No ozone generation

-

Low thermal load on the substrate

-

Long service life of the LED modules

How UV-LED hardening works

What does this technology do and how does it work?

How UV-LED hardening works

What does this technology do and how does it work?

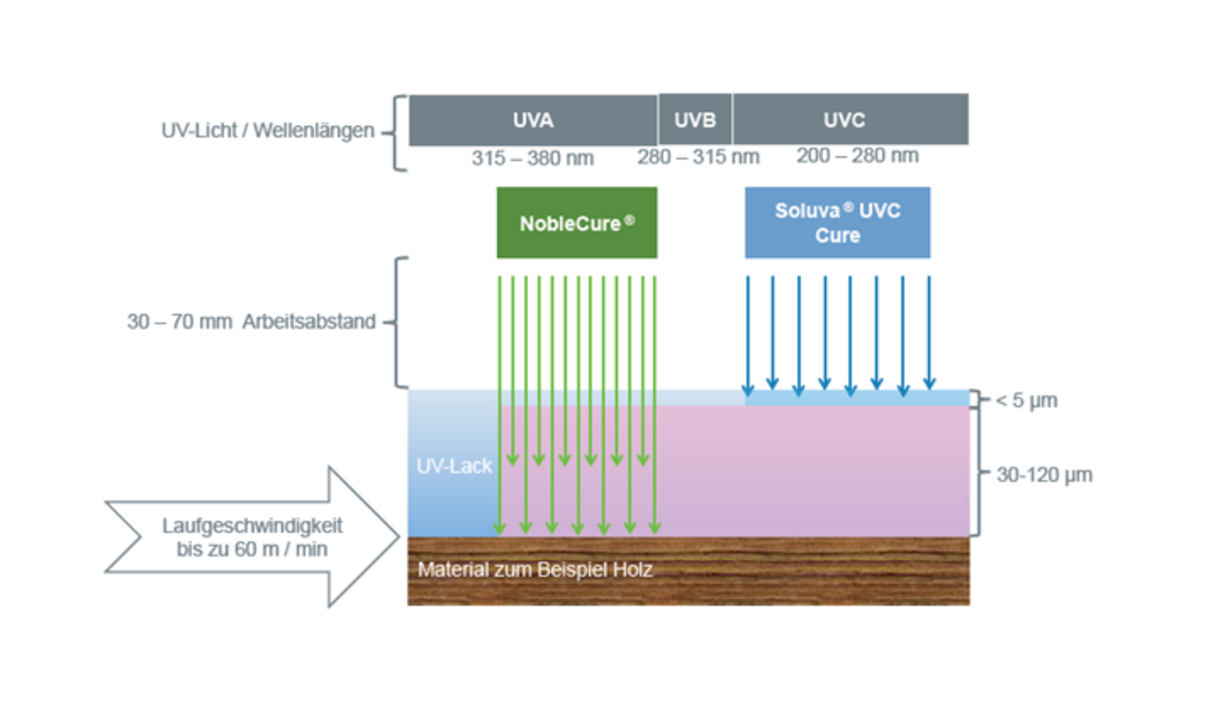

UV hardening is based on starting a radical chain reaction that leads to the formation of bonds in the binder base. This is common to both traditional hardening and hardening using UV light from LED lamps. The difference between the two systems lies in the way the light is generated and in the composition of the UV light emitted. Traditional mercury vapour lamps produce a broad spectrum of radiation from the UV-C spectrum to the range of infrared radiation (thermal radiation). The spectrum can be modified by means of doping with foreign atoms such as gallium. The generation of this radiation is very energy-intensive and associated with high heat generation.

UV-LED lamps, on the other hand, produce almost monochromatic UV light. Standard wavelengths are 365nm, 385nm, 395nm or 405nm. There is practically no emission of radiation in the infrared range, which is a significant advantage in addition to the lower energy consumption. The substrate is not thermally loaded and is not subject to yellowing.

The advantages at a glance

- Reduced energy use and costs

- Eco-friendly, since the diodes produce no ozone and only little CO2 formation

- Eco-friendly, since they don’t contain heavy metals, including mercury and gallium

- Long service life of the UV-LEDs

- No start-up time, can be switched on and off without delay

- Compact design

- Cold UV light

Contact partner