UP Knifing putty PP 8090-9343

Two-component putty with a polyester base, fast-drying, highly ductile, no sinkage, good sanding properties and universally usable.

Enquire articlePage content

- Good coverage and build

- universally usable

- For the automotive industry

- Can be sanded to a powder

- Fast-drying

Areas of application

For removing imperfections in the substrate and filling repaired surfaces and edges. Can be used for all interior fittings, including kitchen and bath.

Technical information

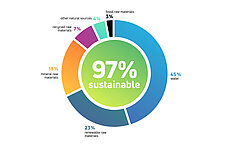

Sustainability data sheet

Certificates

Technical Specifications

| Mixing ratio (volumetric) | 50 : 1 |

|---|---|

| Mixing ratio (gravimetric) | 100 : 1 |

Processing Instructions

| Drying | 5 h / 20 °C |

|---|---|

| Stackable according to | 5 h / 20 °C |

| Surface sanding (grain size) | 180 - 280 |

| Intermediate sanding (grain size) | |

| Yield per pass | m²/l |

| Processing information | Apply one to two coats with hand trowel on prepared substrate. Allow the putty layer to dry thoroughly. After successful intermediate sanding, the next layer of putty can be applied. Attention: do not add more material than can be applied properly in 5 minutes! |

| Special notes | Exotic woods such as macassar or knotty pine with an extremely high resin content must be prime with suitable isolating primers (e.g. PU Isolating primer DG 4720-0001). The lowest amounts of peroxide residue in the dry putty layer could trigger a chemical reaction with certain PU lacquers, creating a yellow-brown discolouration. Therefore, only use peroxide-containing lacquer systems to coat the putty layer! |

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.