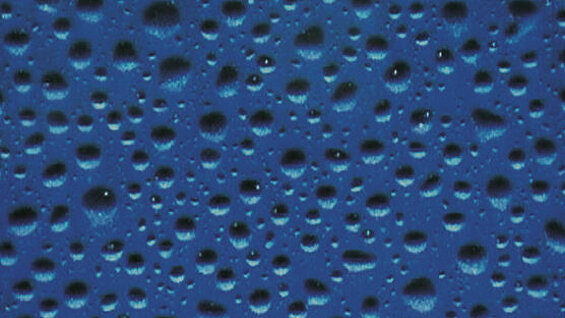

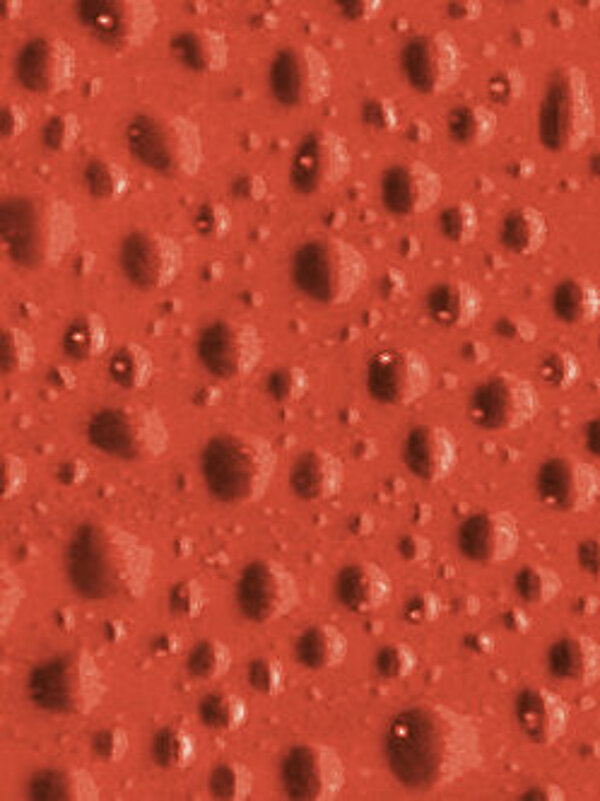

Surfaces appearing to have raindrops

Surfaces appearing to have raindrops

An impressive effect that mimics a lacquered surface wetted with water droplets. Imaginative creative accents for surfaces on interior fittings, such as office furniture, tables, etc. Specifically for use on dark, deep tones, such as dark blue, dark green or black; also suitable for coating behind glass and priming with Glass lacquer Basecoat DG 4744 (coating process in reverse order).

How to – Raindrop effect

- Ensure that priming foil, laminated chipboard or MDF surfaces are well sanded

- Prime with 1 x 150 - 200 g/m² PU Isolating filler DP 491-9343, mixing ratio (by volume) 4 : 1 with PU Hardener DR 405 and diluted with 10 % PU Thinner DV 490

- Allow to dry for at least 16 h / 20 °C

- Sand at 280 - 320 grit

- Apply 1 x 100 - 150g/m² UNA-COLOR DB 45245-(base tone), mixing ratio 10 : 1 with PU Hardener DR 4070 and diluted with 10 % PU Thinner DV 490

- Allow to dry for 2 h / 20 °C

- and continue without intermediate sanding

- Uniformly apply 1 x water using a cup gun with 2 mm nozzle and low pressure; immediately after that mist each droplet on either side (cup gun with 1.2 - 1.5 mm nozzle) one side light the other side dark, so that the drops appear to be three-dimensional

- For example:

- one side with UNA-COLOR DB 45245-102 black

- Mixing ratio 1 : 5 with PU Thinner DV 490

- Then harden this mixture of colour lacquer and thinner at a ratio 1 : 1 with PU hardener DR 4070.

- Rotate the surface by 180°

- and coat the other side with Hesse Metallic Colour concentrate DZ 4995-99042 silver, diluted at a mixing ratio 1 : 1 with DV 490, or optionally DZ 4995-99211 red, DZ 4995-99212 green, DZ 4995-99210 gold, DZ 4995-99042 silver

- Store in a horizontal position

- Allow to dry for at least 16 h / 20 °C

- The best depth effect is achieved by finishing with Brillant lacquer!

- Apply 1 x 100 - 120 g/m² each of DU 45229 PU Acrylic brilliant lacquer, for example, leaving 10 - 60 minutes between coats mixing ratio 2 : 1 with PU Hardener DR 4005 thinned with 40 % PU Thinner DV 4935

- If required, it can be polished to a high gloss after just 24 hours, preferably 72 hours of complete hardening.

Technical Information Raindrop Effect

Products required

- The spray nozzle size and distance from the substrate material affect the size of the droplets.

- This effect can only be achieved on horizontal, flat surfaces (no round edges).

- The surfaces must be stored horizontally.

- Shade each droplet with a reduced spray pressure (0.5 - 1.5 bar) from the side, at as shallow an angle as possible.

- PU lacquers should not be processed and dried at material and room temperatures below 18 °C.

- PU lacquered surfaces should be freshly sanded before finishing to avoid adhesion problems.

- Please conduct a test coating!

Note: This information is purely advisory and is based on the best knowledge available after careful research in line with current state of the art technology. It is not legally binding. We also refer you to our Terms and Conditions. The material safety data sheet according to regulation (EC) No. 1907/2006 is available on request.

Contact partner