Oxi-Reactive-Top oil for roller coating RO 79861

Roller oxide-reactive oil from Hesse results in a beautiful natural wood look with high resistance and sustained protection for your products. Fast thorough curing and great scratch resistance are assured. This product is comparable with conventional UV coatings in terms its of application and suitability for immediate packaging on industrial systems. Conforms with the requirements for naturalness under ÖNORM C 2380.

Artikel anfragen- ISO 22196 antibacterial properties

- DIN 53429 diffusion values

- Free from formaldehyde

- Free from acrylates

Processing

Areas of application

For the coating of panels and flooring made from the typical types of wood. This product is used where the natural character of the wood is to be preserved. Not suitable for smoked oak and heat-treated wood.

Page content

Technical information

Certificates

Technical Specifications

| Proportion of renewable raw materials % | 37,15 % |

|---|---|

| Appearance | colourless |

| VOC EU % | 15,7 % |

| Number of layers (max) | 2 |

| Quantity per layers (min) | 4 g/m² |

| Quantity per layers (max) | 15 g/m² |

| Total quantity applied | 25 g/m² |

Processing Instructions

| Surface sanding (grain size) | 120 - 240 |

|---|---|

| Intermediate sanding (grain size) | |

| Yield per pass | m²/l |

| Processing information | Equipment feed - 15 m/minSubstrate sanding with grit 120 - 24015 g/m² Base oil ROG 7991 with a PU rollerWiping with a Mexico fibre brush - accompanyingWiping with a Mexico fibre brush - contraflow3 infra-red lampsActivation by 3 UV lamps 80 W/cm - 120 W/cm Intermediate smoothing with grit 320 - 400 Scotchbrite roller 5 - 9 g/m² Covering oil RO 79861 with PU roller Activation by 2 - 3 lamps 80 W/cm - 120 W/cm Stacking and packaging is then possibleFurther handling of the finished surfaces, such as producing tongue and groove joints or installing lock systems, is even possible after only around 30 minutes. |

| Special notes | The measured gloss level depends on the application quantity, application process, activation parameters and the condition of the substrate. The stated value accords with the internal Hesse test specifications. |

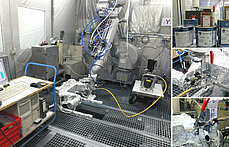

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.