PU Metallic DB 4263x(gloss level)-(colour tone)

Two-component PU acrylate colour lacquer, pigmented, light-fast, opaque, fast-drying and with a uniform colour effect. For effect coatings from open- to closed-pore surface processes. Available in many colours.

Artikel anfragen- uniform colour effect

- light fast

- fast drying and aromatic-free

Processing

Areas of application

For decorative interiors, hotel facilities and furniture surfaces on appropriate PU primers. Certified according to IMO so it can be applied on ship interiors

Page content

Technical information

Certificates

Technical Specifications

| Appearance | opaque |

|---|---|

| Number of layers (max) | 1 |

| Quantity per layers (min) | 80 g/m² |

| Quantity per layers (max) | 120 g/m² |

| Total quantity applied | 120 g/m² |

| Mixing ratio (volumetric) | 10 : 1 |

| Mixing ratio (gravimetric) | 100 : 11 |

Processing Instructions

| Potlife | 24 h / 20 °C |

|---|---|

| Drying | 3 h / 20 °C |

| Due to hardening | 7 d / 20 °C |

| Surface sanding (grain size) | 150 - 320 |

| Intermediate sanding (grain size) | 320 - 400 |

| Yield per pass | m²/l |

| Processing information | The spray nozzle size, air pressure and addition of thinner will influence the effect! Hardening at 5 : 1 with PU Hardener DR 4076-0001 after previously mixing in 5 % Hesse Glass lacquer additive EL 460-0025 to the lacquer component also enables direct application of the lacquer onto glass after proper cleaning. |

| Special notes | Metallic lacquers have to be evenly applied. Application quantities, application methods and drying conditions influence the colour tone and effect. Pre-priming is possible depending on the substrate material and desired surface, e.g. using Hesse PU Isolating filler DP 4791-9343, FANTASTIC-FILL DP 4755-9343 or UNA-COLOR DB 45245-(colour tone). Our Metallic lacquer can be recoated after 4 - 6 h / 20 °C without lacquer sanding to achieve optimised chemical and mechanical resistances and individual gloss levels, e.g. using DE 4259x(gloss level) / DE 55x(gloss level), DE 4877x(gloss level, DE 4503x(gloss level) / DE 56x(gloss level), DU 45540 / DU 520 or DU 45229.We recommend using a soft, dry duster for normal cleaning. Microfibre or leather cloths are suitable for damp cleaning. Wet the cloth in water, wring it out and damp clean. Strong household detergents or abrasive substances are not suitable!This product must only be combined with other approved and technically suitable products when used as a flame retardant coating material for seagoing vessels according to the latest version of SOLAS 74 Reg. II-2/3, II-2/5, II-2/6 and X/3, as amended, IMO Resolution MSC.36(63)-(1994 HSC-Code) 7, IMO Resolution MSC.97(73)-(2000 HSC-Code) 7, IMO MSC/Circ. 1120. The maximum application amount in wet film when using this product as a flame retardant coating material for seagoing vessels is120 g/m². “A risk assessment was undertaken according to Directive 2014/90/EU, Annex II, Section 3. This coating does not pose a physical risk to health nor a risk to the environment when cured and dried.” |

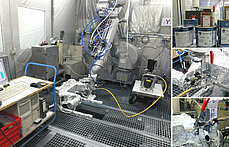

Procedure example

Our technical information is continually adapted to keep up to date with the latest technology and statutory regulations. The latest version is always available online at www.hesse-lignal.de or talk to your local account manager. This information is for advice and is based on the best knowledge available and careful research in line with the current state of the art. This information cannot be held as legally binding. We also refer you to our terms and conditions of business. Safety data sheet is provided in accordance with EC regulation no. 1907/2006.